Component Manufacture

The Manufacturing department in Hycrome has a wide range of capabilities.

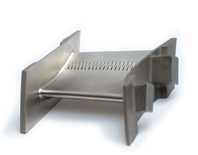

Milling, Turning, Routing, Grinding and Electro-Discharge Machining techniques are employed on a combination of 3 and 4 axis CNC and conventional machines to remove and shape materials to produce components to drawing requirements in a variety of metals.

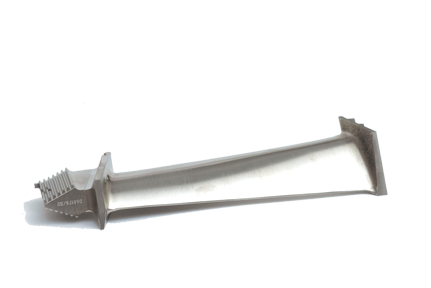

Fast hole drilling is a process used to produce small accurate and deep holes in various components. Holes ranging from 0.25mm to 5mm in diameter and over 150mm deep can be produced if required. These are particularly important for the production of cooling holes on Turbine Blades and Nozzle Guide Vanes.

The Manufacturing section also includes the inspection facility. This utilises various measurement techniques from manual hand held equipment to profile projectors.

In 2014 a 1000 sq.m extension was built to accommodate the expanding CNC machining section.